Vixen CNC Ltd was Established in 1999, and since incorporation has experienced significant growth within the precision machined and cast components industry to become a global supplier enabling them to service all market sectors worldwide specialising in the supply of components used in PPE and height safety systems.

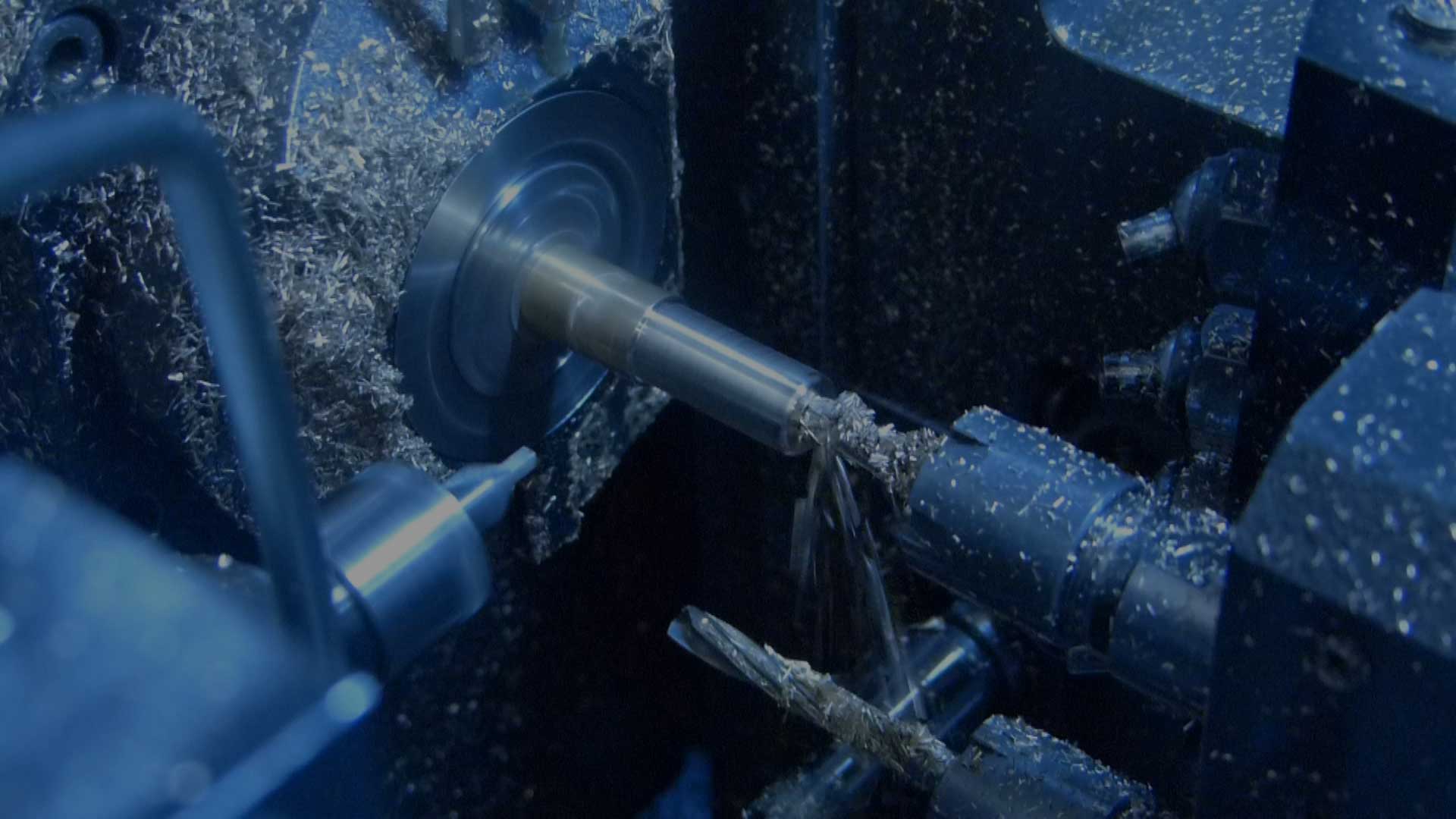

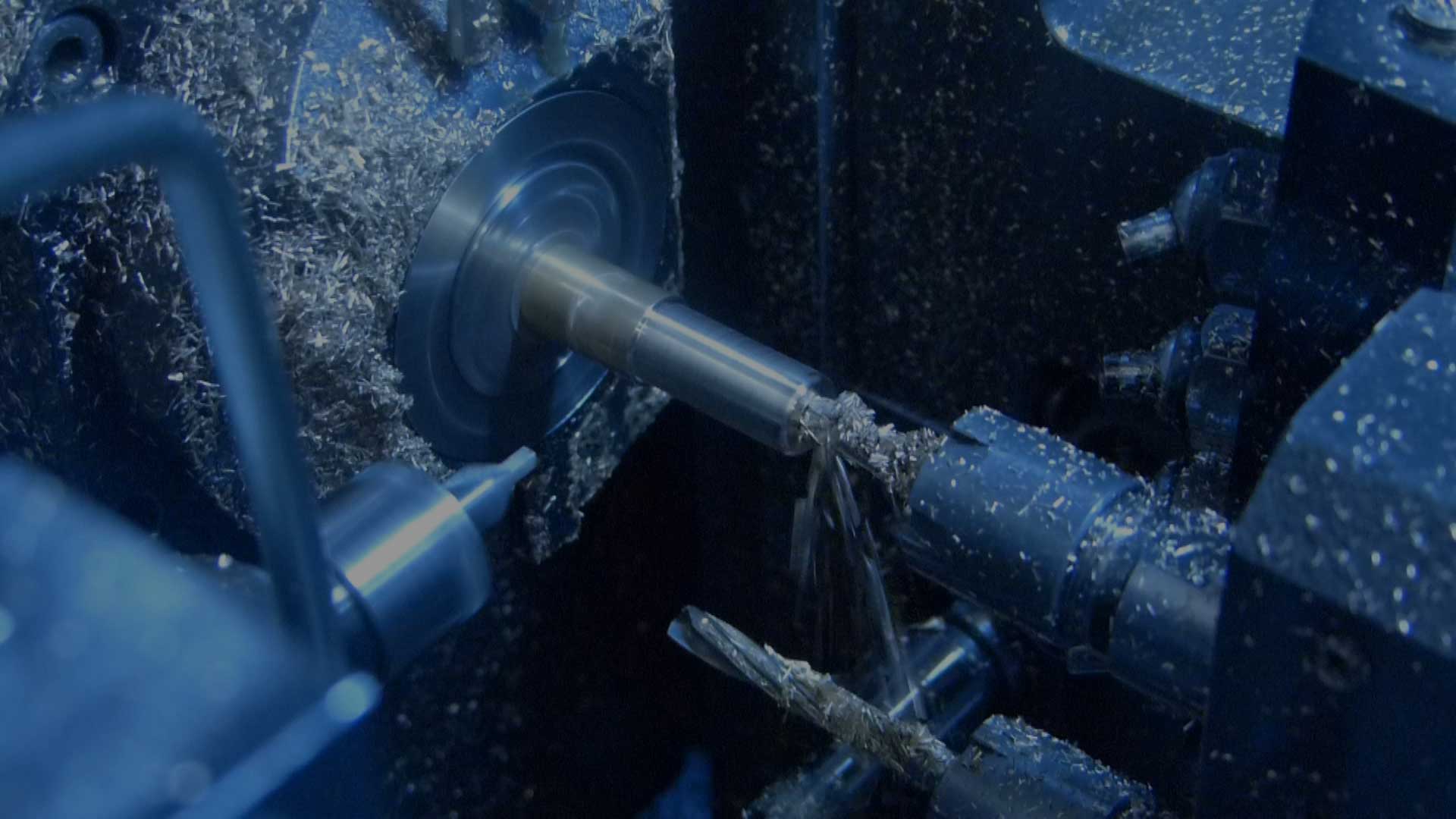

Our extensive investment program has enabled us to maximize efficiency, quality and reduce lead time which in turn has not only led to the growth of Vixen but also forms the basis of the organisation's success. This philosophy allows the company to remain at the forefront of the turned parts industry, the benefits of which are shared with all our customers.

Vixen has a wide engineering skill set and a diverse portfolio of equipment, the company has been able to excel in the primary market of Turned and Milled parts as well as offering a complete in house solution from drawing to finish machined castings and forgings. As can be seen from the plant list we have a number of machines that are identical, thus enabling us to plan any of our core work at short notice without costly re programming or re tooling resulting in shorter lead times and more flexibility.

We are able to offer many in house specialist processes as detailed below, along with complimentary processes carried out by approved suppliers such as stainless steel passivation, plating, heat treatment and anodising. All of our machining processes are carried out daily in any material from brass to exotic materials such as 174Ph stainless, Titanium and Inconel.

Vixen has ISO9001:2015 certification and operates a system of traceability and batch control back to original material source, and a batch marking system as is often required within the safety industry.